High-quality Forged Steel Tank Flanges: A Complete Overview

By:Admin

{Company Name} has been a trusted supplier of forged steel tank flanges for over two decades. Their commitment to excellence and innovation has earned them a strong reputation in the market. The company takes pride in their state-of-the-art manufacturing facilities and a team of skilled engineers and technicians who are dedicated to delivering superior products.

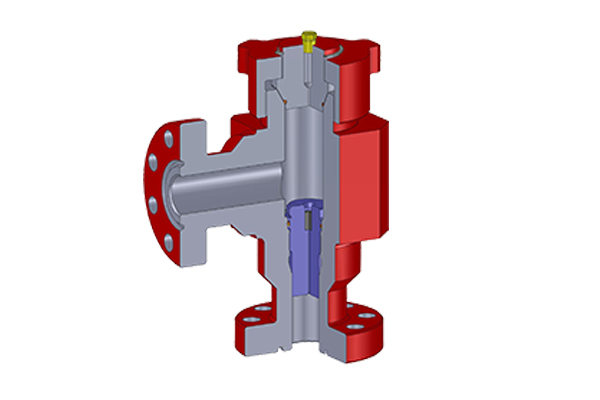

Forged steel tank flanges are critical components in the construction of storage tanks, pressure vessels, and other industrial equipment. They are designed to provide a secure and leak-proof connection between pipes and valves, ensuring the safe and efficient operation of the equipment.

{Company Name} understands the importance of providing flanges that offer exceptional strength and reliability. Their forged steel tank flanges are manufactured using the highest quality materials and advanced forging techniques to ensure superior performance in the most demanding operating conditions.

One of the key advantages of {Company Name}'s forged steel tank flanges is their exceptional resistance to corrosion and high temperatures. This makes them suitable for use in a wide range of industries, including oil and gas, chemical processing, petrochemical, and power generation.

In addition to their outstanding durability, {Company Name}'s forged steel tank flanges are also known for their precise dimensions and tight tolerances. This ensures a perfect fit and alignment, reducing the risk of leaks and mechanical failures in the equipment.

{Company Name} is committed to meeting the diverse needs of their customers. They offer a comprehensive range of forged steel tank flanges in various sizes, pressure ratings, and materials to accommodate different applications and operating conditions. Whether it's a standard design or a custom-engineered solution, {Company Name} has the expertise and capabilities to deliver the right flange for any requirement.

The company's dedication to quality and customer satisfaction has earned them the trust of clients across the globe. {Company Name} has developed strong relationships with leading companies in the industry, who rely on their forged steel tank flanges for their critical applications.

As part of their commitment to continuous improvement, {Company Name} invests in research and development to enhance the performance and reliability of their products. They stay up-to-date with the latest engineering standards and technological advancements to ensure that their forged steel tank flanges meet the evolving needs of the industry.

In conclusion, {Company Name} is a trusted leader in the manufacturing of high-quality forged steel tank flanges. Their unwavering commitment to excellence, innovation, and customer satisfaction has set them apart in the market. With a focus on quality, reliability, and performance, {Company Name} continues to be the preferred choice for forged steel tank flanges in a wide range of industries.

Company News & Blog

Durable and Lightweight Aluminum Plate for Various Industrial Applications

Aluminium Plate, the Robust and Versatile Material for a Wide Range of ApplicationsAluminium is a popular material in various industries due to its lightweight nature, high durability, and corrosion resistance. One of the most common forms of aluminium used in manufacturing and construction is the aluminium plate. These plates are widely used in automotive, aerospace, marine, and construction industries for their structural strength and versatility.One of the leading suppliers of high-quality aluminium plates is {Company Name}. With a strong reputation and years of experience in the industry, {Company Name} has been providing top-notch aluminium products to meet the diverse needs of its clients.Aluminium plates offered by {Company Name} are manufactured using high-grade aluminium alloy, ensuring exceptional strength and durability. These plates are available in various thicknesses, widths, and lengths, making them suitable for a wide range of applications. Whether it's for structural components in aircraft, marine vessels, or architectural elements in buildings, {Company Name}'s aluminium plates are designed to meet and exceed industry standards.In addition to standard aluminium plates, {Company Name} also offers custom fabrication services to cater to specific project requirements. Their team of experienced technicians and engineers can work closely with clients to develop tailored solutions, including cutting, shaping, and finishing of aluminium plates to precise specifications.{Company Name} takes pride in its commitment to delivering high-quality aluminium plates with a focus on sustainability and environmental responsibility. Their manufacturing processes adhere to strict quality control measures and environmental standards, ensuring that their products are not only reliable but also eco-friendly.In recent news, {Company Name} has announced the introduction of a new series of aluminium plates that offer enhanced performance and structural integrity. These new plates are designed to meet the growing demands of industries such as aerospace and automotive, where lightweight yet durable materials are essential for high-performance applications.The new series of aluminium plates boasts improved strength-to-weight ratios, making them ideal for applications that require maximum performance while minimizing weight. With advanced alloy compositions and innovative manufacturing techniques, {Company Name} is set to redefine the standards for aluminium plates in the industry."We are excited to introduce our latest line of aluminium plates that offer unmatched performance and versatility," said a spokesperson for {Company Name}. "These new plates are the result of extensive research and development efforts, and we are confident that they will set a new benchmark for aluminium products in the market."{Company Name} aims to continue its legacy of excellence in providing top-quality aluminium plates and services to its global clientele. With a strong focus on innovation, quality, and customer satisfaction, the company remains at the forefront of the aluminium industry, setting new standards and pushing boundaries in material technology.As industries continue to evolve and demand for high-performance materials increases, the role of aluminium plates in various applications will only continue to grow. With {Company Name} leading the way in delivering exceptional products and solutions, the future of aluminium plates looks promising and full of potential for continued advancements and innovation.

Top Quality Aluminum Casting Parts for Industrial Use

Aluminum Casting Parts Company, a leader in the aluminum casting industry, has been providing high-quality aluminum casting parts for a wide range of industries for over 30 years. The company is dedicated to delivering precision-engineered casting solutions that meet the unique needs of their diverse customer base.With state-of-the-art facilities and a team of highly skilled engineers and technicians, Aluminum Casting Parts Company has the capability to produce a wide variety of aluminum casting parts, including automotive components, aerospace parts, and industrial equipment. The company's commitment to innovation and continuous improvement has positioned them as a trusted partner for businesses seeking reliable and cost-effective casting solutions.One of the key factors that sets Aluminum Casting Parts Company apart from their competitors is their expertise in producing complex and intricate aluminum casting parts. The company takes pride in their ability to tackle even the most challenging casting projects, delivering components that meet the highest standards of quality and precision. This has earned them a reputation as a go-to source for companies in need of intricate aluminum casting parts for their products.In addition to their technical expertise, Aluminum Casting Parts Company is also known for their commitment to sustainable and environmentally friendly manufacturing practices. The company is dedicated to reducing their environmental footprint by employing energy-efficient processes and minimizing waste wherever possible. This commitment to sustainability has not only earned them recognition within the industry but has also positioned them as a preferred supplier for companies looking to align with environmentally conscious partners.Furthermore, Aluminum Casting Parts Company places a strong emphasis on quality control throughout the entire casting process. The company's robust quality assurance program ensures that every part that leaves their facility meets the highest standards of quality and performance. This dedication to quality has resulted in numerous accolades and certifications, further solidifying the company's position as a top-tier provider of aluminum casting parts.The company's commitment to excellence and customer satisfaction has led to strong and lasting partnerships with clients across the globe. From small businesses to multinational corporations, Aluminum Casting Parts Company has proven to be a reliable and trusted partner for companies in need of high-quality aluminum casting parts. The company's ability to deliver on time and within budget has made them a preferred supplier for businesses in a variety of industries.Looking ahead, Aluminum Casting Parts Company remains focused on staying ahead of industry trends and technological advancements. The company continuously invests in research and development to expand their capabilities and offer cutting-edge casting solutions to their customers. By staying at the forefront of innovation, Aluminum Casting Parts Company aims to continue meeting the evolving needs of their clients while maintaining their reputation as a leader in the aluminum casting industry.In conclusion, Aluminum Casting Parts Company has established itself as a premier provider of high-quality aluminum casting parts. With a focus on innovation, sustainability, and quality, the company has earned the trust and confidence of clients worldwide. As the demand for precision-engineered aluminum casting parts continues to grow, Aluminum Casting Parts Company is well-positioned to remain a leader in the industry for years to come.

Top Steel Casting Foundry for High-Quality Metal Components

Steel Casting Foundry is a leading manufacturer of high-quality steel castings for a variety of industries. With a commitment to excellence and a focus on innovation, Steel Casting Foundry has established itself as a trusted partner for customers around the world.Established in [year], Steel Casting Foundry has a long history of producing top-quality steel castings for a wide range of applications. The company's state-of-the-art facilities and advanced manufacturing processes ensure that customers receive products that meet the highest standards of quality and performance.Steel Casting Foundry's team of experienced engineers and metallurgists work closely with customers to develop custom solutions that meet their specific needs. Whether it's a complex component for the automotive industry or a critical part for the energy sector, Steel Casting Foundry has the expertise and capabilities to deliver results.In addition to its commitment to quality, Steel Casting Foundry places a strong emphasis on sustainability and environmental responsibility. The company has implemented a number of initiatives to reduce its environmental impact, including energy-efficient manufacturing processes and the use of recycled materials.Furthermore, Steel Casting Foundry is dedicated to the safety and well-being of its employees. The company has implemented rigorous safety protocols and training programs to ensure that all employees can work in a safe and healthy environment.Steel Casting Foundry's dedication to excellence and customer satisfaction has earned it a reputation as a trusted partner in the industry. The company's products are used by customers in a wide range of industries, including automotive, aerospace, energy, and construction.In order to meet the growing demand for its products, Steel Casting Foundry has continued to invest in its manufacturing capabilities. The company has recently expanded its facilities and acquired new equipment to increase production capacity and improve efficiency.Steel Casting Foundry's commitment to innovation is evident in its ongoing research and development efforts. The company is constantly exploring new technologies and materials to enhance the performance and durability of its products.As a global leader in steel casting manufacturing, Steel Casting Foundry is proud to serve customers around the world. The company has a strong international presence, with a network of sales and distribution partners in key markets.Looking ahead, Steel Casting Foundry is poised for continued growth and success. The company remains committed to delivering the highest quality products and exceptional customer service, while also pursuing new opportunities for innovation and expansion.In conclusion, Steel Casting Foundry is a trusted partner for customers in a wide range of industries, delivering top-quality steel castings and custom solutions. With a focus on excellence, sustainability, and innovation, the company is well-positioned for continued success in the global marketplace.

How to Forge a Hub Wheel: A Step-By-Step Guide

Forging Hub Wheel: A New Milestone in Manufacturing ExcellenceIn the rapidly evolving world of manufacturing and technology, the importance of precision and efficiency cannot be overstated. One leading company at the forefront of this evolution is {}, a renowned industry leader in producing high-quality forged products. With a commitment to innovation and excellence, {} has recently unveiled its latest achievement: the forging of a state-of-the-art hub wheel that is set to revolutionize the automotive and manufacturing industries.The new forging hub wheel represents a significant advancement in the field of manufacturing, as it showcases {}'s expertise in producing complex and intricate forged components with unmatched precision and durability. This groundbreaking achievement is the result of extensive research and development, coupled with years of experience and expertise in the forging industry.With a focus on delivering superior quality and performance, {} has established itself as a trusted partner for customers seeking high-precision forged components. The company's dedication to innovation and continuous improvement has enabled it to stay ahead of the curve, setting new standards for excellence in the industry.The forging process used to create the hub wheel involves the shaping of metal using immense pressure and heat, resulting in a component that is incredibly strong and resistant to wear and tear. By leveraging advanced forging techniques and cutting-edge technology, {} has been able to produce a hub wheel that meets the highest industry standards, setting a new benchmark for quality and reliability.The forging hub wheel is designed to deliver exceptional performance in a wide range of applications, particularly in the automotive sector. Its robust construction and superior strength make it an ideal component for use in vehicles, where reliability and durability are of paramount importance. Whether it's for commercial trucks, passenger vehicles, or off-road vehicles, the forging hub wheel is poised to set new standards for performance and longevity.In addition to its exceptional mechanical properties, the forging hub wheel also boasts a sleek and modern design that reflects {}'s commitment to innovation and aesthetics. By combining form and function, the company has created a product that not only performs flawlessly but also exudes a sense of style and sophistication.As {} continues to push the boundaries of what is possible in the world of forging, the unveiling of the hub wheel represents a significant milestone for the company and the industry as a whole. With its unwavering dedication to excellence and a relentless pursuit of innovation, {} is poised to continue driving progress and setting new standards for manufacturing excellence.The successful forging of the hub wheel is a testament to the company's ability to push the boundaries of what is achievable in the field of forging. By combining cutting-edge technology with traditional craftsmanship, {} has once again demonstrated its ability to deliver superior quality and performance in its products.Looking ahead, {} is committed to building on this success and further expanding its capabilities in the forging industry. With a focus on continuous improvement and a dedication to meeting the evolving needs of its customers, the company is well-positioned to continue leading the way in forging excellence.In conclusion, the forging hub wheel represents a remarkable achievement for {}, showcasing the company's expertise in producing high-precision forged components that set new standards for quality and reliability. By pushing the boundaries of what is possible in the world of forging, {} has once again solidified its position as a leading innovator in the industry. As the company continues to advance its capabilities and explore new frontiers, the unveiling of the hub wheel is undoubtedly a sign of exciting things to come.

Top Advantages of Steel Casting for Industrial Applications

Steel Casting Company Achieves Milestone in ProductionThe Steel Casting Company, based in (location), has recently achieved a significant milestone in their production process, marking a pivotal moment in their growth and success in the industry. The company, which specializes in producing high-quality steel castings for a variety of applications, has continuously strived to improve their production capabilities and expand their market presence. With this recent achievement, they have demonstrated their commitment to excellence and innovation in the manufacturing of steel castings.Established in (year), the Steel Casting Company has built a strong reputation for delivering superior quality castings to their customers. Their state-of-the-art facility is equipped with advanced technology and machinery, allowing them to produce a wide range of steel castings that meet the stringent requirements of various industries, including automotive, aerospace, energy, and construction. Their team of highly skilled engineers and technicians are dedicated to ensuring that each casting meets the highest standards of quality and precision.The recent milestone in the company's production process is the result of their continuous efforts to enhance their manufacturing capabilities. Through strategic investments in new equipment and technologies, the Steel Casting Company has been able to significantly increase their production capacity and efficiency. This has enabled them to meet the growing demand for their products and expand their customer base. Additionally, their commitment to sustainable and environmentally friendly manufacturing practices has further strengthened their position as a responsible and forward-thinking industry leader.As a testament to their dedication to innovation and excellence, the Steel Casting Company has also achieved various certifications and accreditations, ensuring that their products adhere to the highest industry standards. Their adherence to strict quality control measures and thorough testing procedures has earned them the trust and confidence of their customers, who rely on the company to provide reliable and durable steel castings for their critical applications.The Steel Casting Company's success is also attributed to their strong emphasis on customer satisfaction. They prioritize building long-lasting relationships with their clients by offering personalized solutions, technical support, and on-time delivery of their products. Their commitment to understanding the unique needs of each customer and providing tailored solutions has set them apart in the competitive steel casting market.In addition to their dedication to manufacturing excellence, the Steel Casting Company is also an active participant in the community and actively contributes to various charitable initiatives and environmental conservation efforts. They recognize the importance of giving back to society and strive to make a positive impact through their corporate social responsibility programs.Looking to the future, the Steel Casting Company remains focused on continuous improvement and innovation. They aim to further expand their product range, explore new market opportunities, and strengthen their position as a leading provider of high-quality steel castings. By staying true to their core values of quality, reliability, and customer satisfaction, they are confident in their ability to achieve even greater milestones in the coming years.In conclusion, the recent achievement of the Steel Casting Company in their production process is a testament to their unwavering commitment to excellence and innovation. By continuously investing in advanced technology and enhancing their manufacturing capabilities, they have positioned themselves as a formidable force in the steel casting industry. Their dedication to quality, customer satisfaction, and sustainable practices sets them apart as a trusted and respected partner for businesses in need of top-notch steel castings. With a clear vision for the future and a solid foundation of success, the Steel Casting Company is poised for continued growth and prosperity in the years ahead.

High-Quality Casting Machinery for Industrial Use

Casting Machinery, a renowned leader in the manufacturing and distribution of casting equipment, has recently announced the launch of their latest innovation in casting technology. With a strong focus on precision, efficiency, and reliability, this new machinery is set to revolutionize the industry and set a new standard for quality casting.Founded in 1998, Casting Machinery has been at the forefront of innovation in the casting industry for over two decades. With a dedication to research and development, the company has consistently strived to push the boundaries of what is possible in the field of casting technology. Their commitment to excellence has earned them a reputation as a trusted and respected leader in the industry.The new casting machinery, which has been in development for several years, represents the culmination of Casting Machinery's extensive research and engineering expertise. The company's team of highly skilled engineers and technicians have worked tirelessly to bring this cutting-edge technology to life, and the result is a machine that offers unparalleled precision and efficiency.One of the key features of the new machinery is its advanced control system, which has been designed to ensure optimum casting quality and consistency. This state-of-the-art system is capable of monitoring and adjusting a wide range of parameters in real time, allowing for precise control over the entire casting process. This level of control not only ensures superior casting quality, but also allows for increased productivity and reduced waste.In addition to its advanced control system, the new machinery also incorporates the latest in casting technology, including innovative molding and casting processes. These processes have been carefully developed to minimize defects and imperfections in the final cast products, resulting in a higher yield of top-quality castings.Furthermore, the new machinery has been designed with efficiency in mind. With improved energy efficiency and reduced cycle times, this equipment offers significant cost savings for casting manufacturers. These cost savings, coupled with the improved casting quality, make this machinery a highly attractive investment for companies looking to stay ahead of the competition.To ensure that customers are able to make the most of this new technology, Casting Machinery is also offering comprehensive training and support services. These services are designed to help customers integrate the new machinery into their operations seamlessly, and to provide ongoing support and maintenance to maximize the performance and longevity of the equipment.With the launch of this new machinery, Casting Machinery is once again demonstrating its commitment to innovation and excellence in the casting industry. As the industry continues to evolve and demand for high-quality castings grows, this new technology is poised to set a new standard for precision, efficiency, and reliability.Casting Machinery's dedication to pushing the boundaries of what is possible in the casting industry has made them a trusted partner for companies around the world. With the launch of this new machinery, they are continuing to lead the way in shaping the future of casting technology, and setting the bar for quality and performance in the industry.

High-Quality Forged Steel Flanges for Durable and Reliable Connections

Forged Steel Flanges: A Key Component in the Oil and Gas IndustryThe oil and gas industry relies heavily on the use of high-quality, durable components to ensure the safety and reliability of its operations. One such component is the forged steel flange, which is an essential part of pipelines, valves, and other equipment used in the transportation and processing of oil and gas. These flanges are designed to connect pipes, valves, and other equipment, thereby providing a convenient access point for inspection, cleaning, or modification.In the industry, the demand for forged steel flanges has been steadily increasing, driven by the growth of oil and gas exploration and production activities. As a result, companies are constantly seeking reliable and reputable suppliers of these critical components. One such supplier is [Remove Brand Name], a leading manufacturer of forged steel flanges.[Remove Brand Name] has established itself as a trusted supplier of high-quality forged steel flanges to the oil and gas industry. The company prides itself on its commitment to quality, precision, and reliability, which are essential characteristics for components used in critical applications such as oil and gas processing. With state-of-the-art manufacturing facilities and a team of experienced engineers, [Remove Brand Name] is able to produce a wide range of forged steel flanges that meet the stringent requirements of the industry.The manufacturing process of forged steel flanges is a complex and precise operation that requires meticulous attention to detail. [Remove Brand Name] utilizes advanced forging techniques and employs strict quality control measures to ensure that its flanges meet the industry's exacting standards. The company also offers custom forging services, allowing it to produce flanges in various sizes, shapes, and materials to meet the specific needs of its customers.In addition to its manufacturing capabilities, [Remove Brand Name] is also dedicated to providing exceptional customer service. The company works closely with its clients to understand their requirements and ensure that its products meet their expectations. Whether it's a standard forged steel flange or a custom-designed component, [Remove Brand Name] is committed to delivering reliable and high-performance solutions to its customers.The quality and reliability of [Remove Brand Name]'s forged steel flanges have made it a preferred supplier for many leading companies in the oil and gas industry. Its products are used in a wide range of applications, including offshore drilling, pipeline construction, refining, and petrochemical processing. The company's flanges are known for their durability, strength, and resistance to corrosion, making them well-suited for the demanding conditions found in the oil and gas sector.[Remove Brand Name] recognizes the importance of sustainability and environmental responsibility in the oil and gas industry. As a result, it has implemented sustainable practices in its manufacturing processes, such as efficient use of resources and waste reduction. The company is also committed to complying with industry regulations and standards for environmental protection, ensuring that its products are not only reliable but also environmentally friendly.Looking ahead, [Remove Brand Name] continues to invest in research and development to further enhance the performance and reliability of its forged steel flanges. By leveraging the latest technologies and innovations, the company aims to remain at the forefront of the industry and continue meeting the evolving needs of its customers.As the demand for oil and gas continues to grow, the importance of high-quality forged steel flanges cannot be overstated. These critical components play a vital role in ensuring the integrity and safety of the industry's infrastructure. With its unwavering commitment to quality and reliability, [Remove Brand Name] is well-positioned to continue serving as a trusted partner for companies in the oil and gas sector, providing them with the essential components they need to maintain efficient and safe operations.

Innovative Weight Pad Revolutionizes Fitness Tracking and Monitoring

The use of pressure-sensitive weight pads has revolutionized various industries by providing accurate and reliable data for a multitude of applications. These weight pads, also referred to as pressure pads, offer an innovative solution for measuring weight distribution, monitoring activity levels, and detecting changes in pressure. One company at the forefront of this technology is leading the way in providing high-quality weight pads for a wide range of industries.With a dedication to innovation and excellence, the company has established itself as a premier provider of weight pads. Their cutting-edge technology and commitment to customer satisfaction have set them apart in the market. The weight pads offered by the company are designed to meet the diverse needs of industries such as healthcare, sports and fitness, transportation, and more.In the healthcare industry, weight pads play a crucial role in patient care and rehabilitation. By accurately measuring weight distribution and pressure points, healthcare professionals can gain valuable insights into a patient's condition and tailor their treatment accordingly. The company's weight pads have been widely adopted in hospitals, rehabilitation centers, and elder care facilities, where they have proven to be an invaluable tool for improving patient care outcomes.Furthermore, in the sports and fitness industry, weight pads are used to track and analyze movement patterns, gait analysis, and weight distribution during physical activities. Coaches, trainers, and athletes rely on the data provided by weight pads to optimize training programs, prevent injuries, and enhance performance. The company's weight pads have become a staple in sports science laboratories, physical therapy clinics, and athletic training facilities, where they are instrumental in improving athletic performance and reducing the risk of injuries.In the transportation industry, weight pads play a crucial role in ensuring safety and efficiency. By accurately measuring the weight distribution and load balance of vehicles, weight pads help prevent overloading and ensure compliance with regulations. The company's weight pads are widely used in trucking, logistics, and agricultural industries to optimize load distribution, improve fuel efficiency, and reduce the risk of accidents.The company's commitment to quality and innovation is reflected in the advanced features of their weight pads. Their products are equipped with state-of-the-art sensors and wireless connectivity, allowing for real-time data collection and analysis. The weight pads are durable, portable, and easy to use, making them suitable for a wide range of applications and environments. Additionally, the company offers customizable solutions to meet the specific needs of their clients, ensuring that their weight pads are tailored to their unique requirements.As a leading provider of weight pads, the company continues to lead the way in advancing the capabilities and applications of this technology. Their ongoing research and development efforts focus on enhancing the accuracy, reliability, and versatility of their weight pads. By staying at the forefront of technological advancements, the company is well-positioned to meet the evolving needs of their customers and maintain their competitive edge in the market.In conclusion, weight pads have become an indispensable tool across various industries, and the company's cutting-edge technology and commitment to excellence have solidified their position as a leading provider of high-quality weight pads. With a dedication to innovation and customer satisfaction, the company is poised to continue driving advancements in the field of weight pad technology. With their state-of-the-art products and exemplary track record, the company is well-positioned to meet the growing demand for reliable and accurate weight measurement solutions across industries.

The Importance of Bucket Teeth for Construction Equipment

Komatsu is a well-known and reputable company that manufactures heavy equipment and machinery for the construction, mining, and forestry industries. One of the most important components of their machinery is their bucket teeth, which are essential for the efficient operation of their excavators, loaders, and other equipment.The bucket teeth are the cutting edges of the buckets attached to the heavy machinery, and they are crucial for ensuring that the equipment can effectively dig, lift, and transport materials on construction sites, in mines, and in forestry operations. Komatsu's bucket teeth are renowned for their durability, strength, and precision engineering, making them highly sought after by construction and mining companies around the world.One of the key features of Komatsu's bucket teeth is their advanced design, which allows for maximum digging and loading performance. These bucket teeth are specifically engineered to withstand the intense pressures and forces that heavy equipment is subjected to during excavation and material handling tasks. This ensures that the machinery can continue to operate at peak efficiency, even in the most challenging working conditions.In addition to their exceptional durability, Komatsu's bucket teeth are also designed for easy installation and removal, allowing for quick and efficient maintenance and replacement. This is essential for minimizing downtime and ensuring that the heavy machinery can remain operational for extended periods, increasing productivity and reducing operating costs for construction and mining companies.Furthermore, Komatsu's bucket teeth are manufactured using high-quality materials and cutting-edge production techniques, ensuring that they meet the highest industry standards for reliability and performance. This commitment to quality and excellence has solidified Komatsu's reputation as a leading provider of heavy equipment and machinery components worldwide.Komatsu's dedication to innovation and continuous improvement is evident in their ongoing research and development efforts to further enhance the performance and durability of their bucket teeth. By leveraging the latest advancements in materials science, engineering, and manufacturing technologies, Komatsu is able to produce bucket teeth that deliver superior performance and longevity, giving their customers a competitive edge in their respective industries.Moreover, Komatsu's commitment to sustainability and environmental responsibility is reflected in their efforts to optimize the design and materials used in their bucket teeth, reducing waste and minimizing the environmental impact of their production processes. This aligns with their broader corporate initiatives to promote sustainable practices and reduce the carbon footprint of their operations.In conclusion, Komatsu's bucket teeth are a testament to the company's dedication to excellence, innovation, and customer satisfaction. By delivering high-quality, durable, and reliable components for their heavy machinery, Komatsu continues to play a pivotal role in advancing the construction, mining, and forestry industries. As they continue to push the boundaries of engineering and manufacturing, Komatsu is poised to remain a trusted partner for companies seeking the best-in-class equipment and components for their operations.

Quality Aluminium Casting Parts for Various Applications

Aluminium Casting Parts - a Cornerstone of {}'s Manufacturing Expertise{} is a leading company in the manufacturing industry, specializing in producing high-quality aluminium casting parts. With a commitment to excellence and a strong focus on innovation, {} has become a trusted partner for customers in a wide range of industries, including automotive, aerospace, and industrial equipment.Aluminium casting parts are an integral part of {}'s product portfolio, and the company has invested heavily in state-of-the-art casting technology to ensure the highest level of quality and precision. From complex components for aircraft engines to intricate parts for high-performance automobiles, {} has the capabilities to meet the diverse needs of its customers.One of the key advantages of aluminium casting is its ability to produce parts with complex geometries and thin walls, while maintaining high strength and durability. This makes it an ideal choice for a wide range of applications, where lightweight and high-performance components are essential. With its expertise in aluminium casting, {} is able to deliver parts that meet the most stringent requirements for performance, reliability, and safety.In addition to its technical capabilities, {} is also committed to sustainability and environmental responsibility in its manufacturing processes. The company has implemented advanced technologies and practices to minimize waste, reduce energy consumption, and lower its carbon footprint. By prioritizing sustainability, {} not only benefits the environment but also enhances the long-term value it delivers to its customers.One of the key strengths of {} is its ability to work closely with customers to develop custom solutions that meet their specific needs. Through close collaboration and a deep understanding of their requirements, {} is able to design and produce aluminium casting parts that are tailored to the unique demands of each application. This customer-centric approach has been a driving force behind {}'s success and has earned the company a reputation for excellence in the industry.As the demand for lightweight, high-performance components continues to grow across industries, the market for aluminium casting parts is expected to expand significantly. {} is well-positioned to capitalize on this opportunity, thanks to its strong technical expertise, advanced manufacturing capabilities, and commitment to customer satisfaction. By consistently delivering top-quality products and exceptional service, {} aims to solidify its position as a leader in the aluminium casting industry.In conclusion, aluminium casting parts are an essential component of {}'s manufacturing expertise, and the company is dedicated to delivering superior solutions to its customers. With a focus on innovation, sustainability, and customer collaboration, {} is poised for continued success in the dynamic and competitive world of manufacturing. As the demand for high-quality aluminium casting parts continues to rise, {} remains at the forefront of the industry, providing innovative and reliable solutions for a wide range of applications.